Technology

We specialize in the production of durable and sustainable activewear, casual wear apparel and equipment. We use world-renowned technology and creative approaches to achieve our mission - helping you turn your brand vision into reality

– Digital Printing

— Screen printing 16 colors

— Screen water-based ink

— Rubber printing

—Boxed Printing

– Holographic Printing

– Sublimation

– All Over Printing

– Vinyl and Flocking

– Embroidery (Regular, Strip Applied, Tanaka, High Point, Chain Stitch, English)

Dot Effect, Fuwari, Sequins, Rope with Ribbons and Ropes with metal chains)

—High frequency

— Embroidery with sequins and beads

— Bonded seams (woven fabrics)

— All types of fusion processes

— Special effects (foils, membranes…)

WORK WITH A VARIETY OF FABRICS AND MATERIALS

MATERIALS

We try to be as versatile as possible when it comes to fabric structures , weights and compositions. Here the list of those we use most frequently:

— Jersey

— Jacquard

— Fleece

— Piqué

— Interlock

— Rib

— Satin

— Canvas

— Double face

— Bonded fabrics

— Woven

— Flannel

— Denim

— Twill

— Sherpa

— Corduroy

Our most commonly used fibers

FIBERS

Fabrics compositions may include a wide variety of fibres. Here is a list our most commonly used fibres:

— Cotton (Organic / recycled)

— Wool

— Linen

— Polyamide

— Polyester/ recycled polyester

— Modal

— Lyocell

— Viscose

— Tencel

— Cupro

— Cashmere (for jersey)

— Acetate

— Triacetate

— Elastane

— Rayon

Fabrics & Dyeing

We create you salesman samples for your future production

We are one of the few garment manufacturers with our own fabricand dyeing department/ line This office is tasked with procuring suitable productswhich are monitored from prototyping right through to the finished product. The bestbenefit being that the run rates can be optimized to match your core productdevelopment in the main line , consequently enhancing efficiency and costs.CFB green way : All fabric waste from the cutting process is reused to make new fabricsfrom recycled cotton/ or recycled polyester

WE USE GOTS AND RECYCLED FABRICS

ECO FRIENDLY

All of our cotton is grown using natural fertilizers and pesticides. In addition, genetically modified seeds are not used in their cultivation, which helps to conserve seed biodiversity and soil fertility.

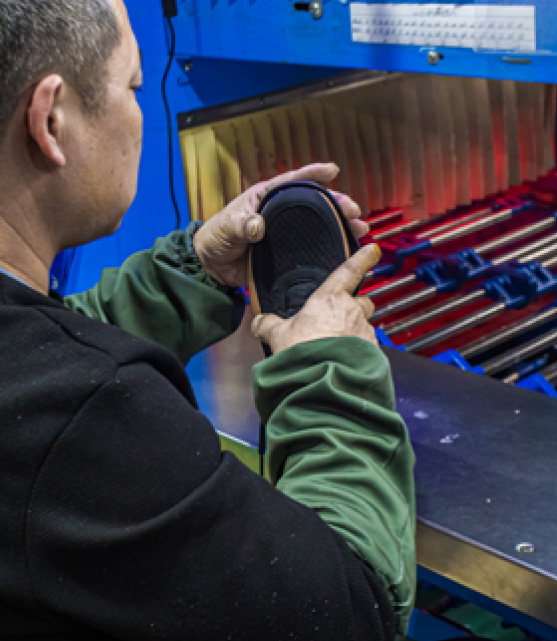

DIVERSIFIED PRODUCTION

Providing the production of a variety of products, including shoes, gloves, protective equipment and mixed martial arts equipment. Diversified production capabilities help our customers become more competitive

—Gloves

—Box Glove

—Shoes

—MMA Glove

—Protectives

—Spirring Glove

—Accessories

Suitable for equipment fabrics and materials

MATERIALS

Our equipment uses environmentally friendly materials with good quality and performance, which are durable, corrosion-resistant, safe and harmless. Therefore, the products have a long service life, conform to the concept of environmental protection, are environmentally friendly, and achieve sustainable development of manufacturing.

— Material

—Leather

—Microfibre

—PU

PROFESSIONAL EQUIPMENT

Professional equipment can ensure accuracy, consistency and reliability in the

product manufacturing process, thereby reducing the occurrence of human

errors and improving production efficiency and product quality.

The flow production line can optimize the production process, reduce material handling

and waiting time, and shorten the production cycle.